PH: 567-242-2221 TF: 833-242-2221

Weight: 21 lbs

Shipping Dimensions: 25″x25″x13″

$2,365.00

The Mr. Mister misting system is designed to blanket the cutter with a soft water spray while the cutting is in progress. The vapor mitigates the silica particles in the air, which are produced by the ongoing operations. The unit bolts directly to the Mr. Manhole drive motor, comes with all the hardware needed, and requires water from a dealer-supplied water tank.

In stock

| # | Part # | Description |

|---|---|---|

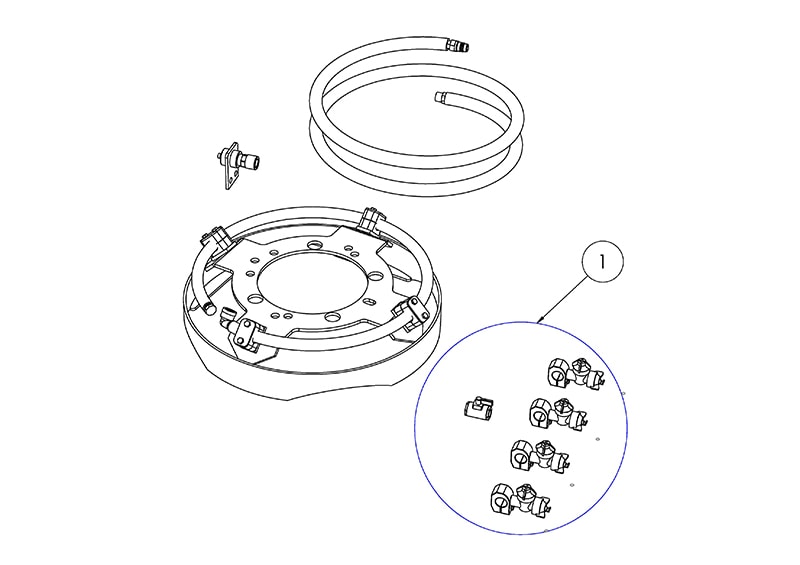

| 1 | K-MM0546 | SPRAY NOZZLE KIT – MR. MISTER |

After 46 years, the Occupational Safety and Health Administration has issued new standards concerning crystalline silica in order to protect workers from exposure. Crystalline silica is dangerous for workers and has been known to cause silicosis, respiratory diseases, lung cancer, and even kidney disease.

As a result of the new silica regulations, Mr. Manhole has developed a new manhole cutter misting system for our tools, which will control silica exposure for your crews and allow you to fully comply with the new regulations.

The Mr. Mister misting system is specifically designed to comply with OSHA silica control regulations. The system uses water to control dust created by cutting concrete and asphalt. The main components are the spray head, which bolts directly to the Model 40 drive motor, the flow control valve, a supply hose, a quick-connect fittings mounting bracket, and all fittings and clamps. Even a handy hose clamp crimping tool is included!

The manhole cutter misting system is designed to work with the skid loader’s supplied water tank and pump, which all manufacturers offer. The flow rate is adjustable, ranging from 0.5 gallons per minute to one gallon per minute.

With the Mr. Manhole cutter tool and Mr. Mister misting system mounted on a skid steer loader, your cutting and removing operation will fall under the category 4.8 vehicle-mounted drilling rig.

By misting the cutting blades with water to mitigate silica dust from spreading and enabling crews to operate from within an approved cab, the Mr. Mister manhole cutter misting system makes sure that these requirements are met.

At Mr. Manhole, we offer an innovative way to cut and remove manhole frames. Our solutions are designed to streamline workflow, ensure safety, and save time and money in the long. Discover our B-52 manhole cutter, Gold Series Six Shooter, and Platinum Series Six Shooter models, and find the right fit for your operations. Combined with the Mr. Mister misting system, you not only gain a streamlined way to tackle manhole removal and restoration, but also ensure compliance with OSHA regulations.

If you are going to remove manhole frames, you will create a silica hazard, and you will need to comply with OSHA regulations. This manhole cutter misting system makes compliance a breeze. Quick, easy, and affordable, the Mr. Mister misting system will be with you for the long haul, keeping workers safe and protecting your operation from liability.

A manhole cutter misting system creates a fine mist around the cutting head to prevent silica particles from going airborne during cutting operations. The key components include a spray head, the flow control valve, a supply hose, a quick-connect fittings mounting bracket, and all fittings and clamps. It’s mounted directly onto the model 40 drive motor.

In short, Mr. Mister misting system meets OSHA silica standards by spraying the dust at the source and turning dangerous silica particles into a slurry that falls on the ground. This method protects ground crews and operators from inhaling crystalline silica and complies with silica exposure regulations.

Our manhole cutter misting system is designed to comply with all up-to-date OSHA regulations for silica exposure and control. By wetting the dust and silica particles with low-flow vapor and operating from within an enclosed cab, our system will protect your crews from dangerous exposure to silica and protect your operations from liability.

Mr. Mister misting system is a bolt-on attachment that can be integrated with a compatible Mr. Manhole drive motor and connected to a water tank and pump supplied by skid steer and loader manufacturers. However, it’s always a good idea to ensure compatibility before retrofits. If you’re unsure whether your system supports it, feel free to contact our team, and we’ll assist you in finding the right fit.

Mr. Manhole goes above and beyond to assist contractors, municipalities, and utility crews around the globe with state-of-the-art solutions for manhole rehabilitation and removal, and that includes a modern way to tackle silica control. With our manhole cutter misting system, you can rest assured that your operations follow the highest safety standards and that your crews are protected from silica exposure.

Our strategies are designed to help you achieve quicker project turnaround, improve workplace safety, and cut labor costs. Whether you need a reliable manhole cutter attachment, a high-quality valve replacement kit, or durable manhole repair products for your projects, we provide all of those and more. Connect with us today, and discover a safer, faster, and more efficient method!