Modern roadways are engineering marvels. They are subjected to the abuse of thousands of cars and trucks rumbling over them day in and day out. They survive the harsh elements of winter cold and summer heat. This amazing durability is no accident but the result of sophisticated time proven engineering. But, they still need to be maintained and repaired.

Modern roadways are engineering marvels. They are subjected to the abuse of thousands of cars and trucks rumbling over them day in and day out. They survive the harsh elements of winter cold and summer heat. This amazing durability is no accident but the result of sophisticated time proven engineering. But, they still need to be maintained and repaired.

The contractors who perform this road construction are highly skilled technicians using state of the art equipment and following a rigid protocol. The work is meticulously inspected and documented.

And, under these artfully crafted roads lie much of the infrastructure that allows society to work. Often, something goes wrong with a pipe or wire that makes up the infrastructure and workers have to remove a section of the road and excavate to expose the utility for repair.

There are just a few ways this has been accomplished to date. Typically a large concrete/asphalt saw is used to cut a square in the road over the affected utility. An air hammer is used to break the pavement out. An excavator or backhoe is brought in to scoop out the area and expose the utility. Silica dust particles are created and must be controlled according to new OSHA rules. This involves either air filtration machines or water misting or both and is expensive and time-consuming.

This process is lengthy and disruptive to traffic. Repairs are never convenient and always impede traffic flow. Workers are in the danger zone during the process.

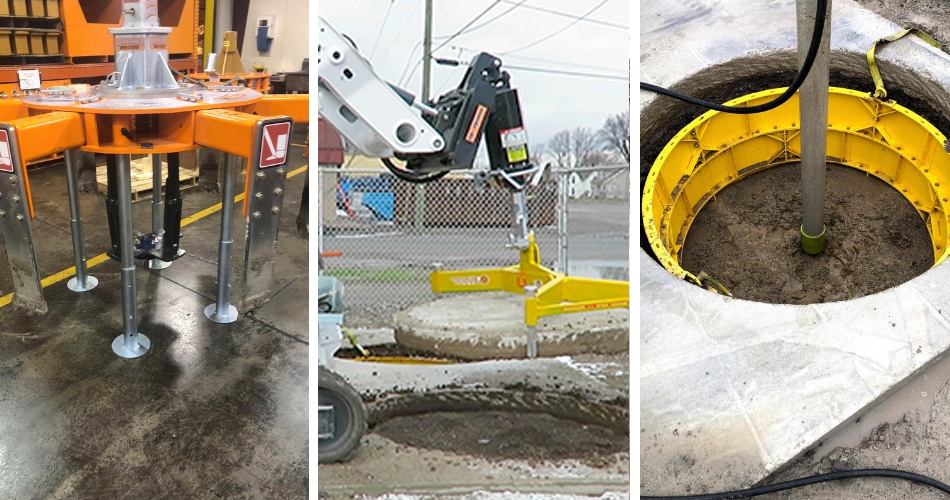

Mr. Manhole has invented a new method for road penetrations. The method is quick, safe, economical, fully engineered, and leaves a beautiful round repair every time. The method employs a round coring machine that attaches to a skid loader like the ones owned by every municipality or contractor. In addition, the system uses a vacuum excavator that most cities already own.

In recent years vacuum excavation has gained popularity. Vacuum excavation is high-pressure air or water blasted into the dirt or stone to loosen it and a large vacuum tube/hose immediately sucking up the rubble. There are some major advantages to vacuum excavating. Number one, it’s faster, the material is loosened, removed, and loaded directly. Nothing is piled on the street or dropped. Number two, it is protective of the utility. A skilled operator can quickly expose a pipe or wire and clean it in preparation for repair without damaging it.

This new method is presented with a full engineering specification ensuring a high-quality repeatable road penetration and restoration every time.

Using the Cookie Cutter system is very simple indeed. Simply drill a 1.25” diameter hole over the affected utility using the included battery powered drill. Cut out the 74” cookie through asphalt or concrete in minutes with our Mr. Manhole cutter. During the process, the operator is protected from silica through our Mr. Mister tool, which is also installed on the cutter.

Once it is cut out, the cookie is lifted directly on a waiting truck via our Cookie Lifter. Next, a round personnel protection cage (certified to 10 feet deep) is placed in the excavation and vacuum excavating begins. The cage slides into place as the excavation is deepened and holds the adjacent fill in place. The utility is exposed and repaired as needed.

The backfill process is well engineered and ensures adequate compaction of fill material leading to a reliable repair at the road surface. The area directly over and around the utility is restored following guidelines established by the utility owner. This includes any coverings or sand etc., which would be needed to directly preserve the utility.

From this stage, the excavation is raised in six-inch compacted lifts using approved fill and raising the cage at each stage. This tiered approach preserves the integrity of the surrounding road base. At the pavement level, simply follow the same stringent requirements set forth in the original road building specifications.

Once complete, the repair has no sharp edges with the potential to crack or maintain. It’s just a smooth, clean repair that is completely waterproof.

This is the only practical, affordable, and fully engineered solution for road penetration in the world. The system protects adjacent pavement and base material and there is virtually no labor required with this system. The system is extremely fast, more economical, and gives a high quality, attractive result every time.

© 2022 Critex LLC All rights reserved. | Contact | Privacy Policy | Sitemap

Website by NOW Marketing Group